-

tel:

+86 15253598306 -

email:

sales@fushijixie.cn

PS Foam Sheet Extusion Line

PRODUCT DESCRIPTION

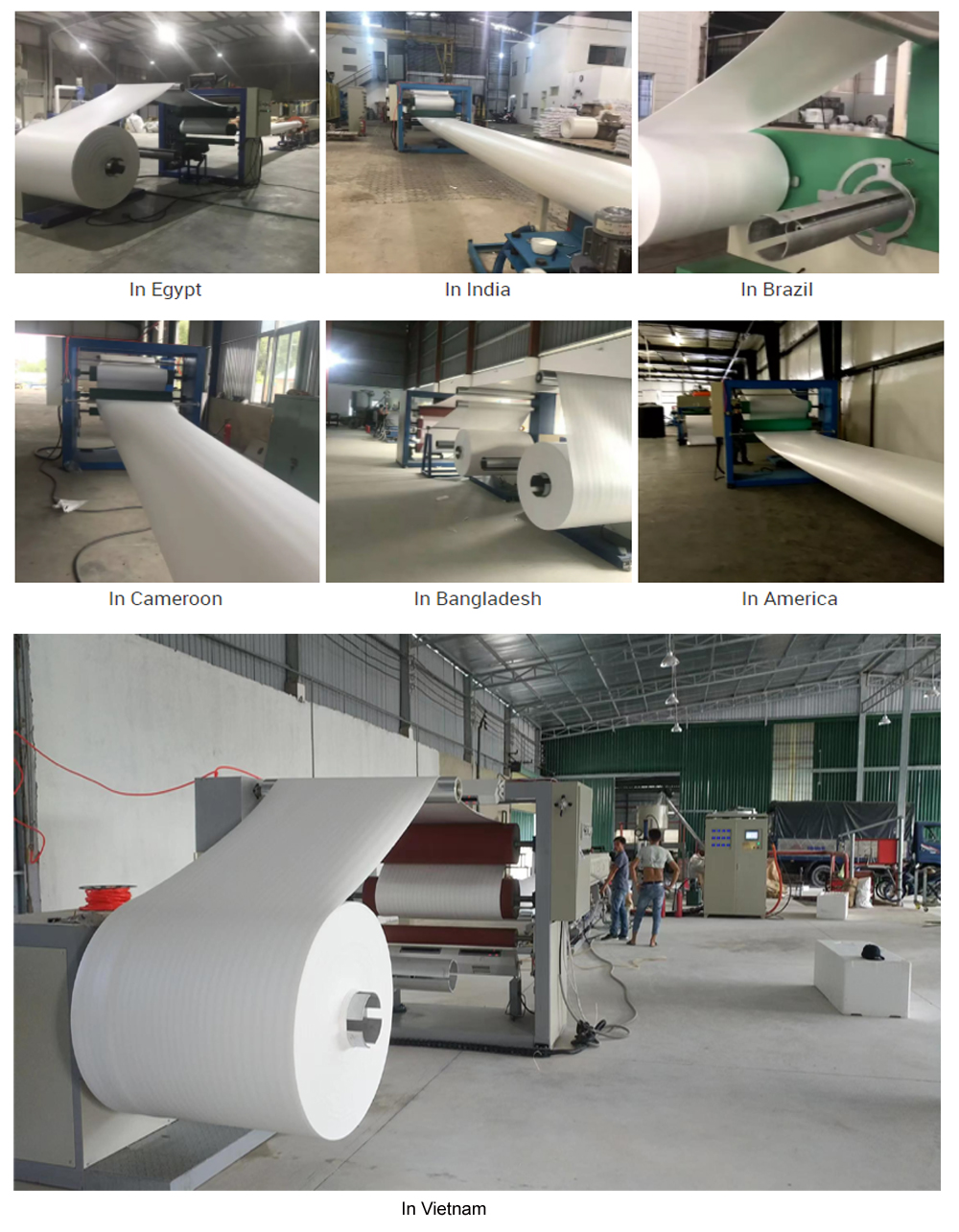

This PS foam sheet extrusion machine produce PS foam sheet, which is a kind of new-type packing with the features of shock proofing, sound insulating, heat preservation, damp proof, safety, and good plasticity. It is used widely in the packing of food, fruit, electronic product, daily necessities, hardware product, advertisement plate, etc.

|

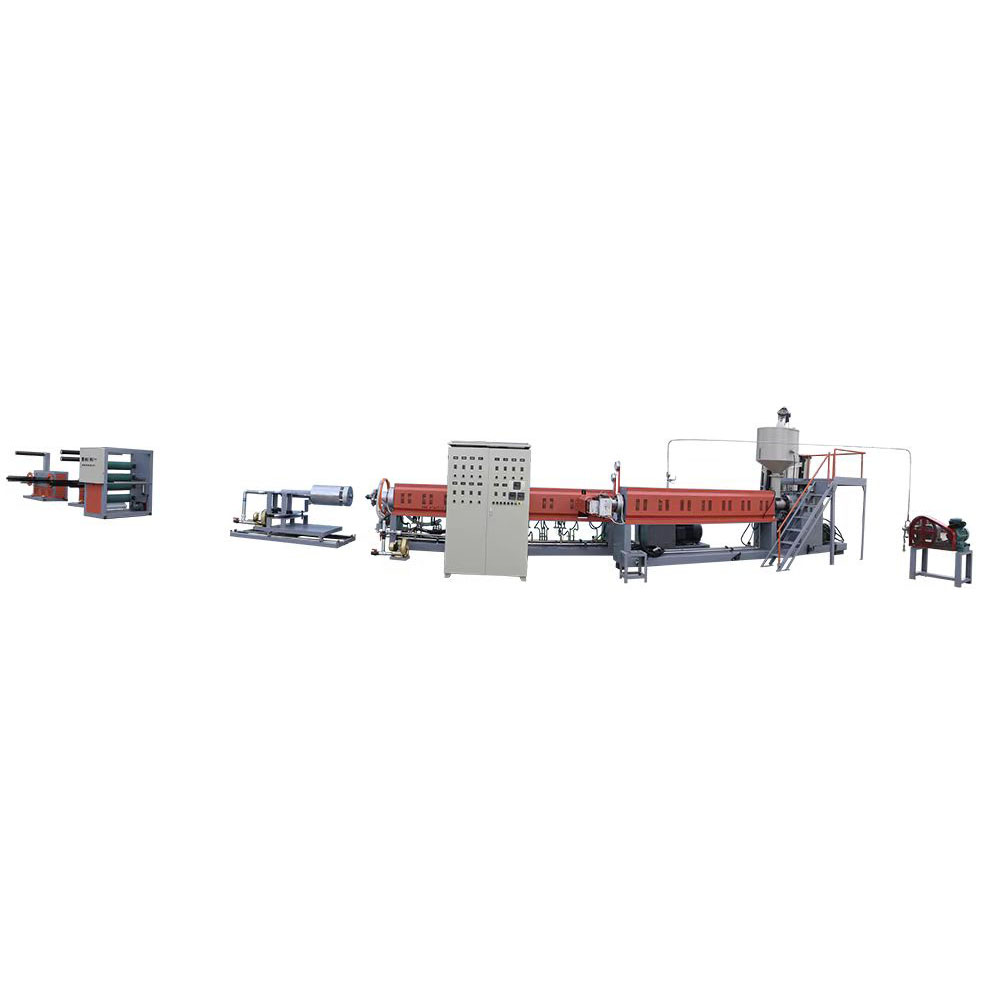

Model

|

FS-FPP75/90

|

FS-FPP105/120

|

FS-FPP120/135

|

FS-FPP135/150

|

|

Foaming Rate

|

20-30

|

20-30

|

20-30

|

20-30

|

|

Width of product(mm)

|

660

|

660-1180

|

660-1180

|

660-1180

|

|

Cutting Mode

|

Single or double cutter

|

|||

|

Thickness of product(mm)

|

1.0-2.0

|

1.0-3.5

|

2.0-5.0

|

2.0-6.0

|

|

Cooling method

|

Air or water cooled

|

|||

|

Output

|

60-90

|

150-220

|

250-320

|

300-350

|

|

Installed Capacity(kw)

|

120

|

200

|

300

|

350

|

|

Dimensions(L*W*H)(m)

|

26*4*2.8

|

30*4.1*2.8

|

38*4.2*3.2

|

40*4.2*3.2

|

|

Total Weight(T)

|

10

|

12

|

18

|

20

|

Main Features

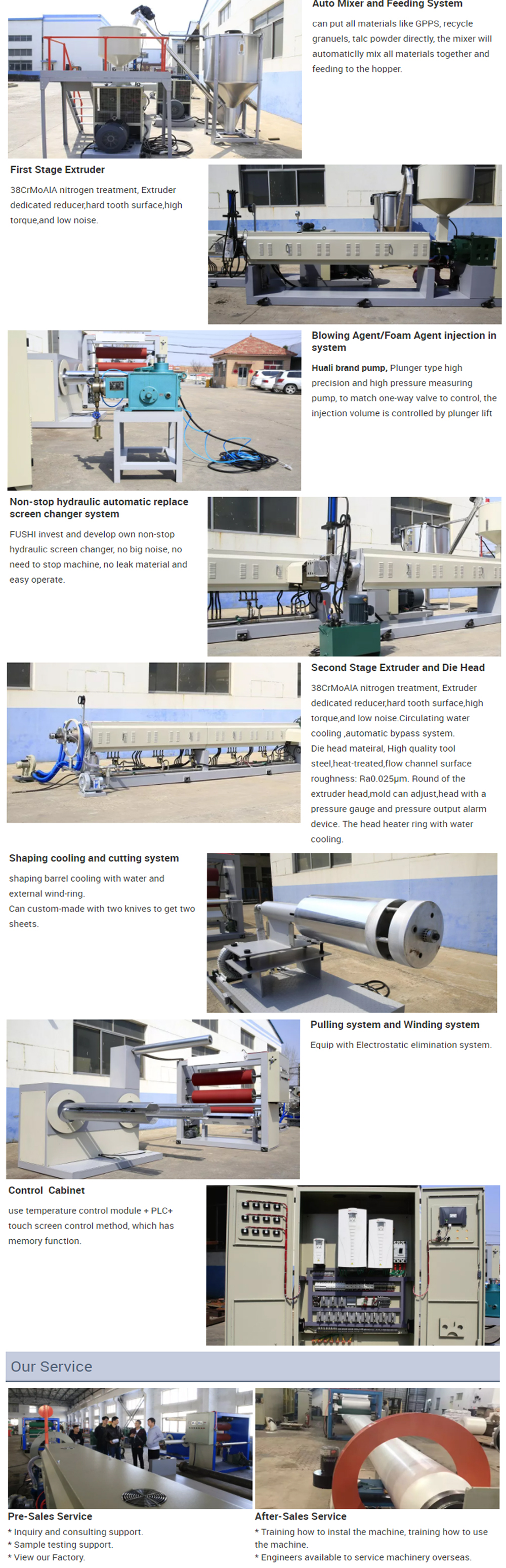

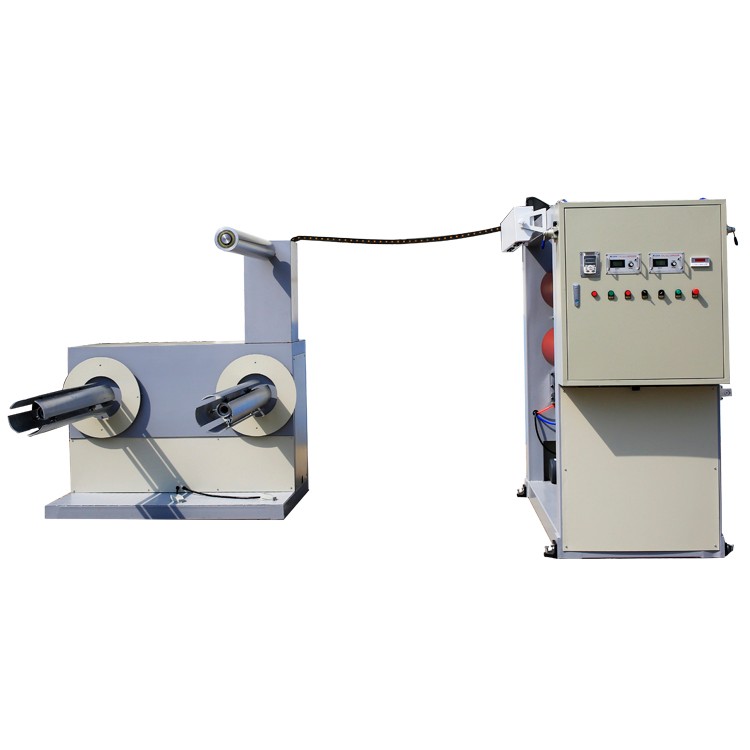

1) Equip with auto mixer and feeding system, can put all materials like GPPS, recycle granuels, talc powder directly, the mixer will automaticlly mix all materials together and feeding to the hopper.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) FUSHI invest and develop own non-stop hydraulic screen changer, no big noise, no need to stop machine, no leak material and easy operate.

4) Running in a high automatization and intellectualization,no pollution